Producten

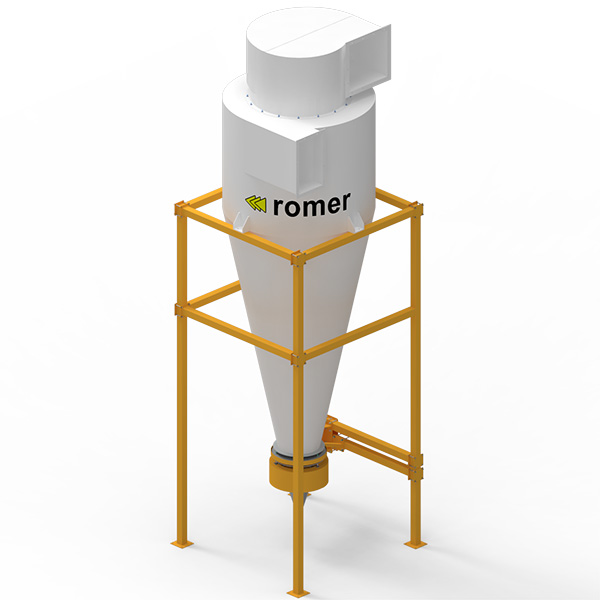

Zarządzanie farbą

Zarządzanie farbą

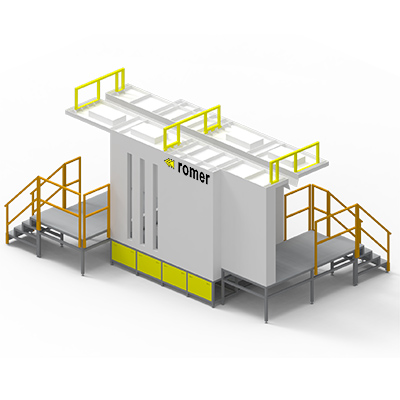

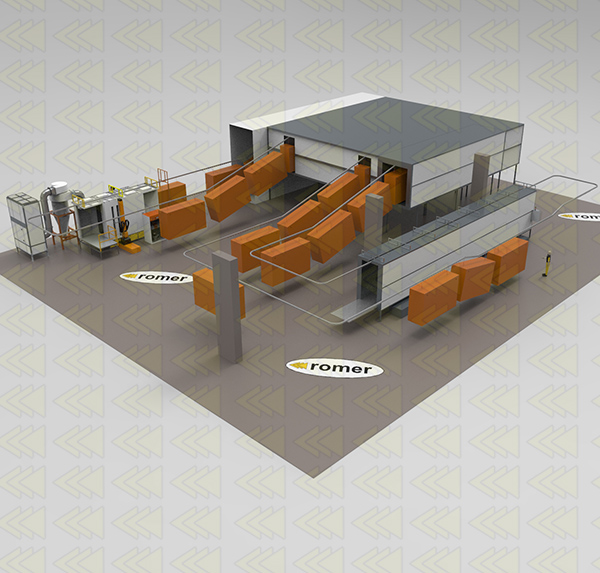

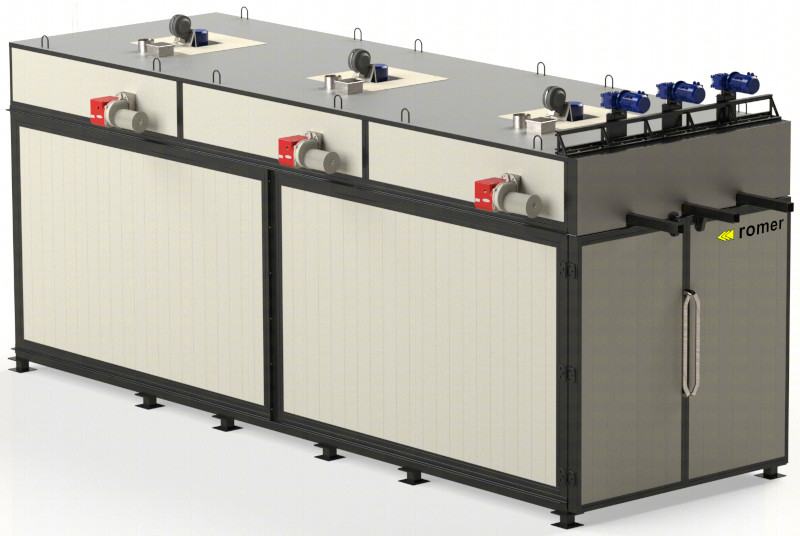

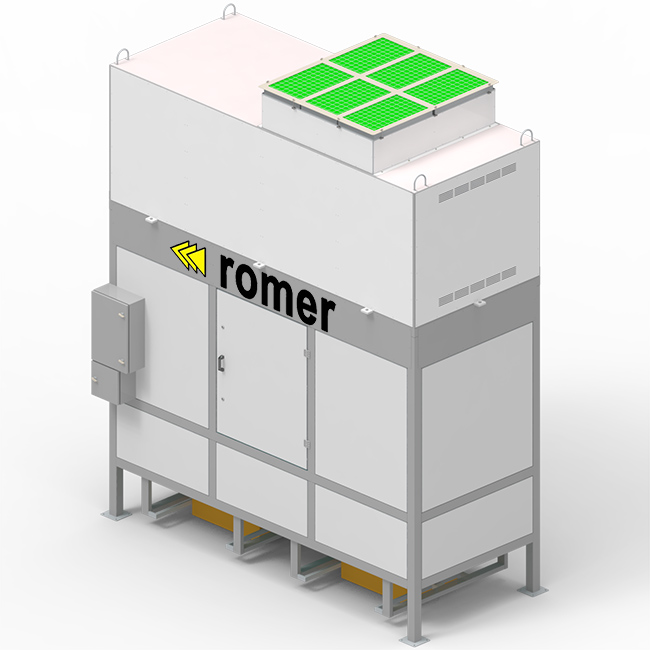

Ovens

Ovens

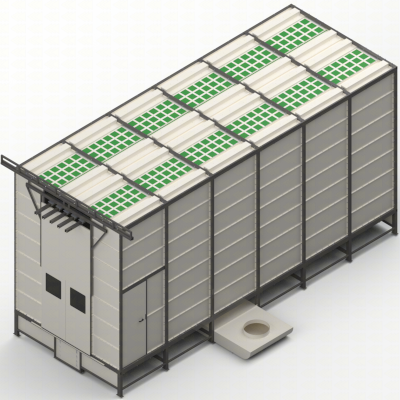

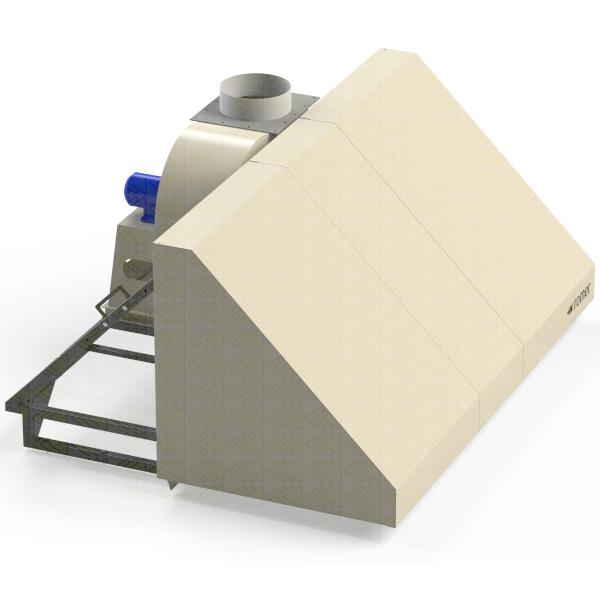

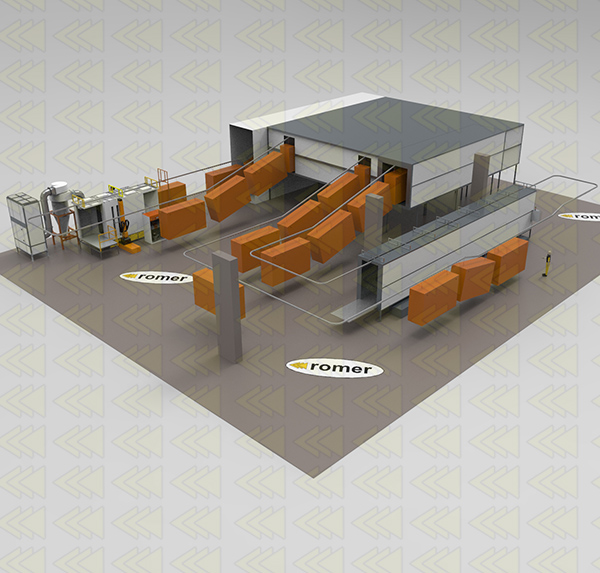

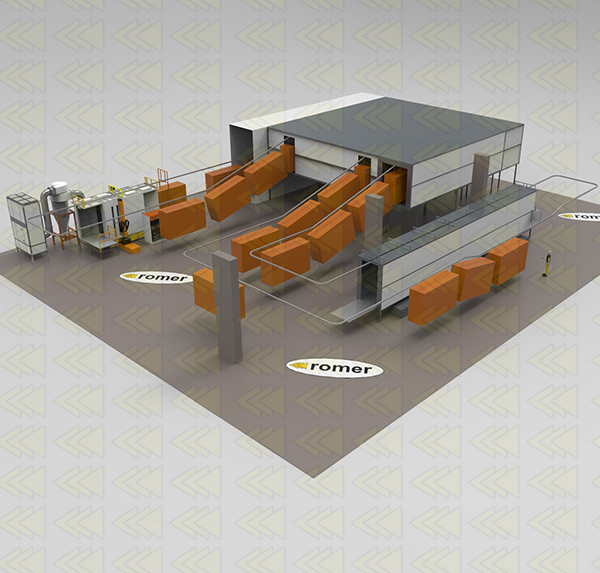

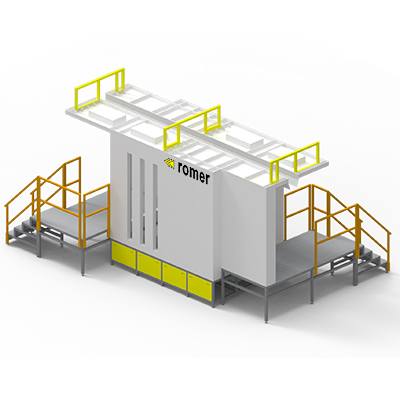

Poedercoatcabines

Poedercoatcabines

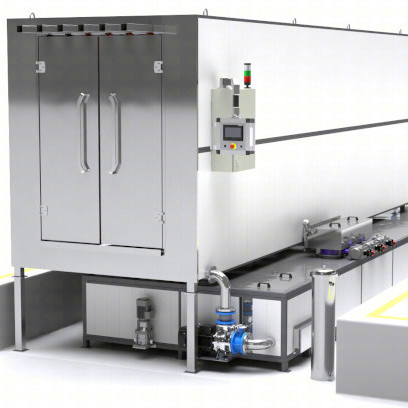

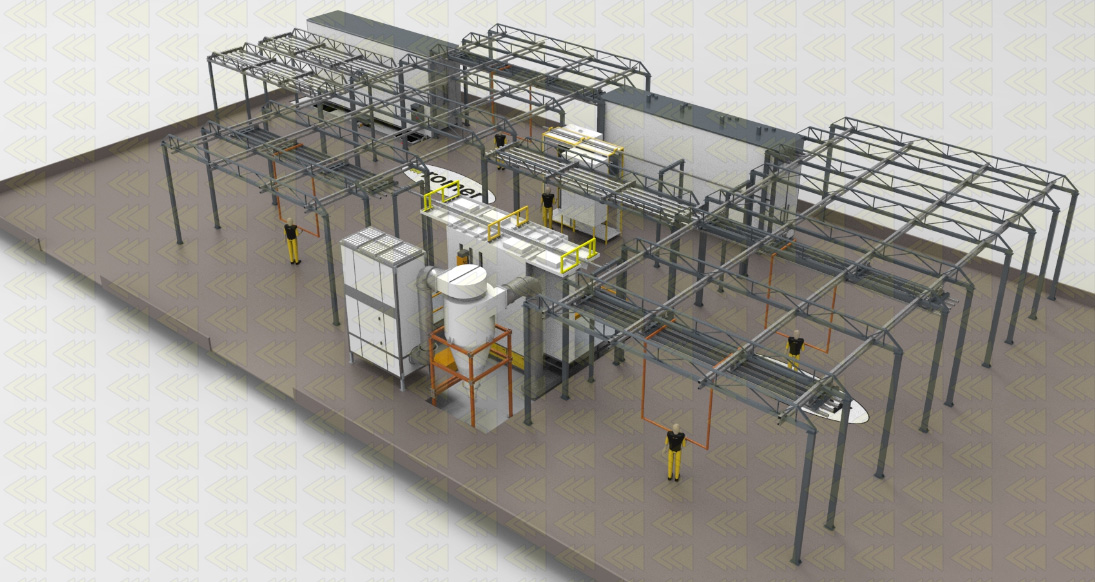

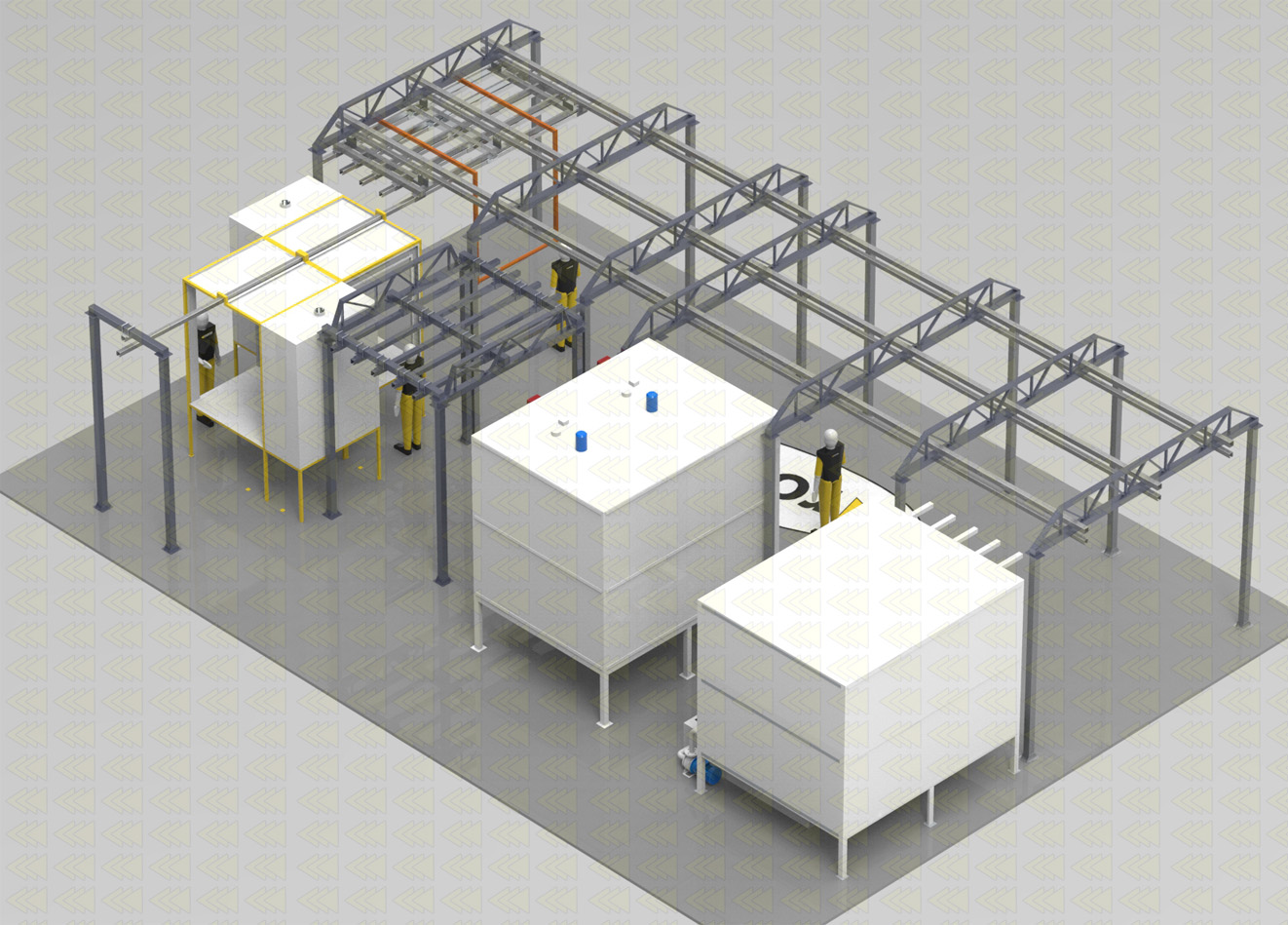

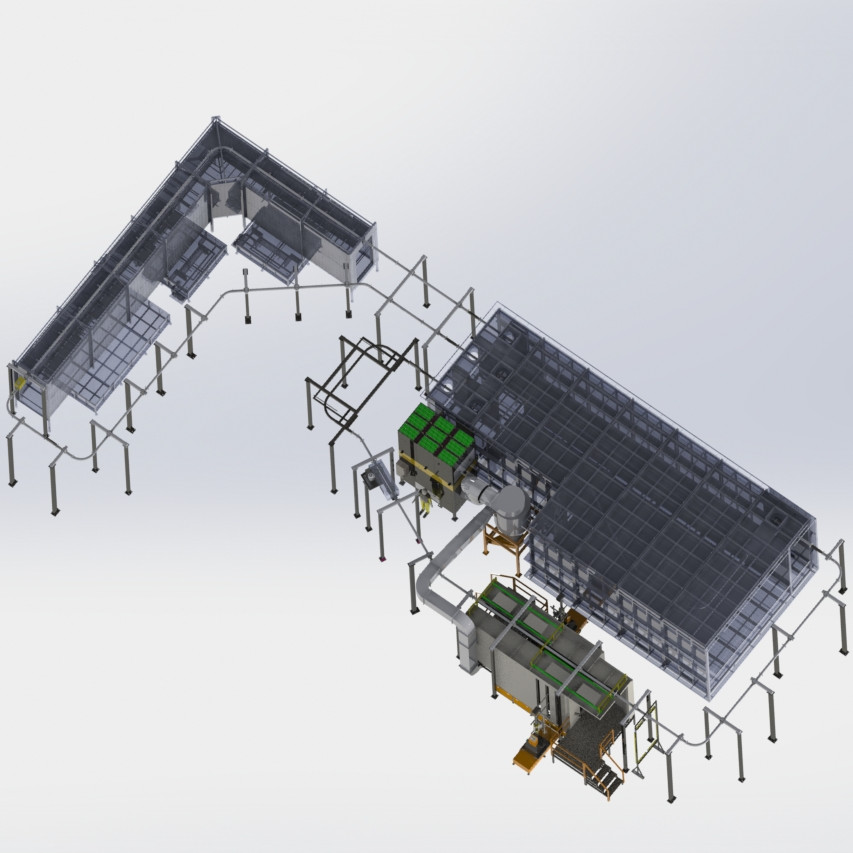

Voorbehandelings

Voorbehandelings

Oczyszczanie ścieków

Oczyszczanie ścieków

Handpoederspuitapparatuur

Handpoederspuitapparatuur

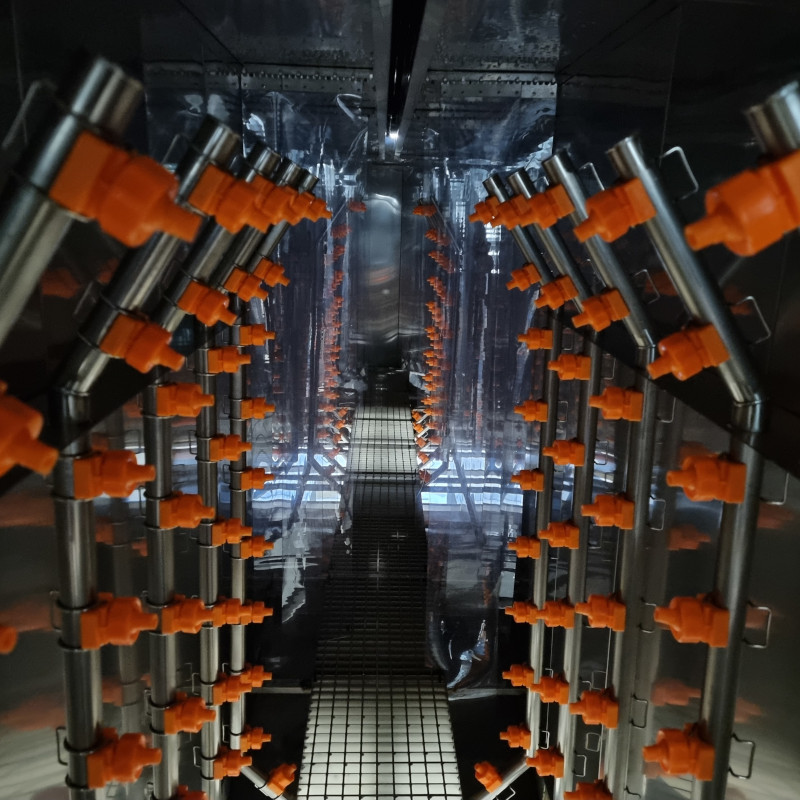

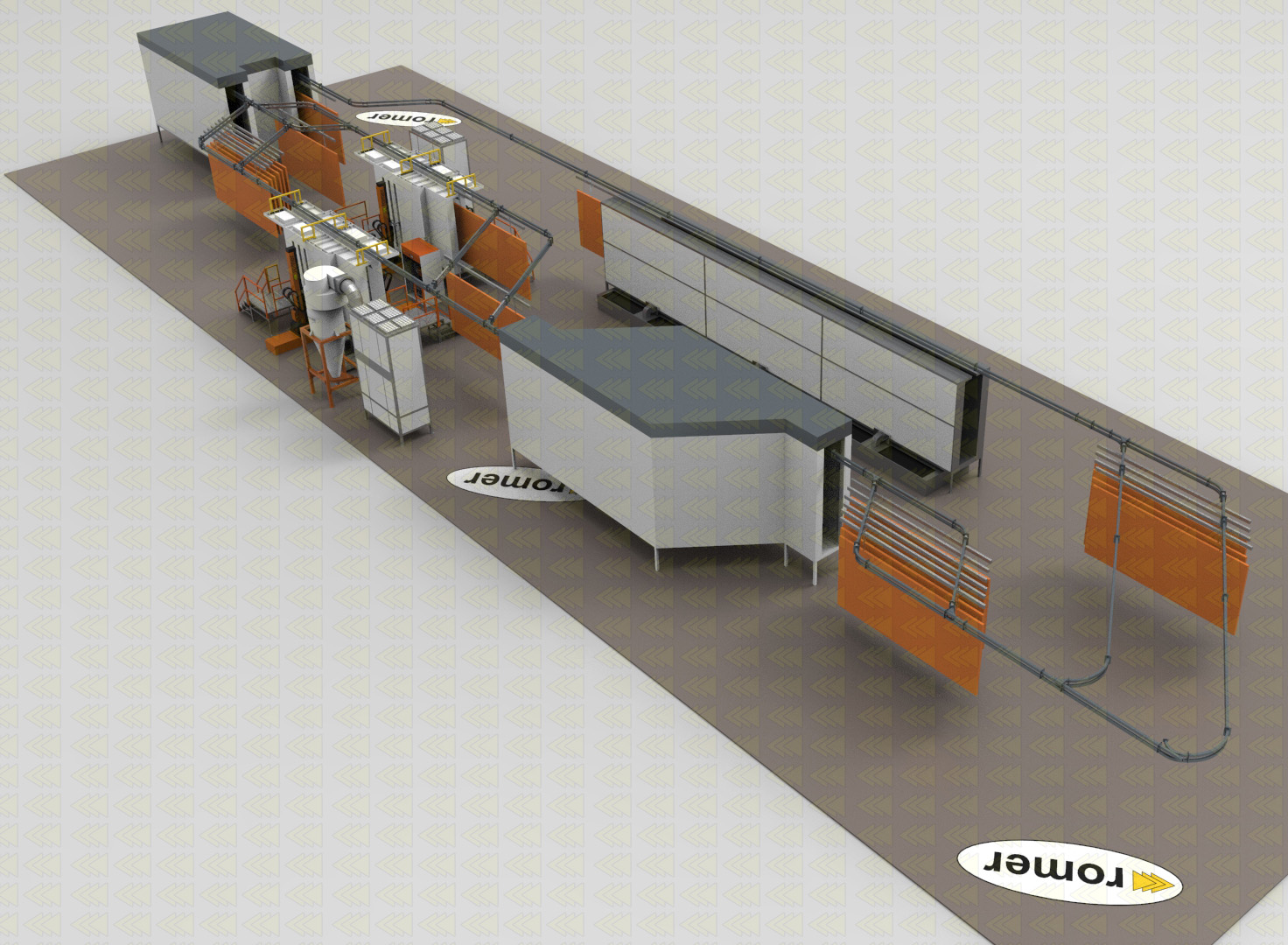

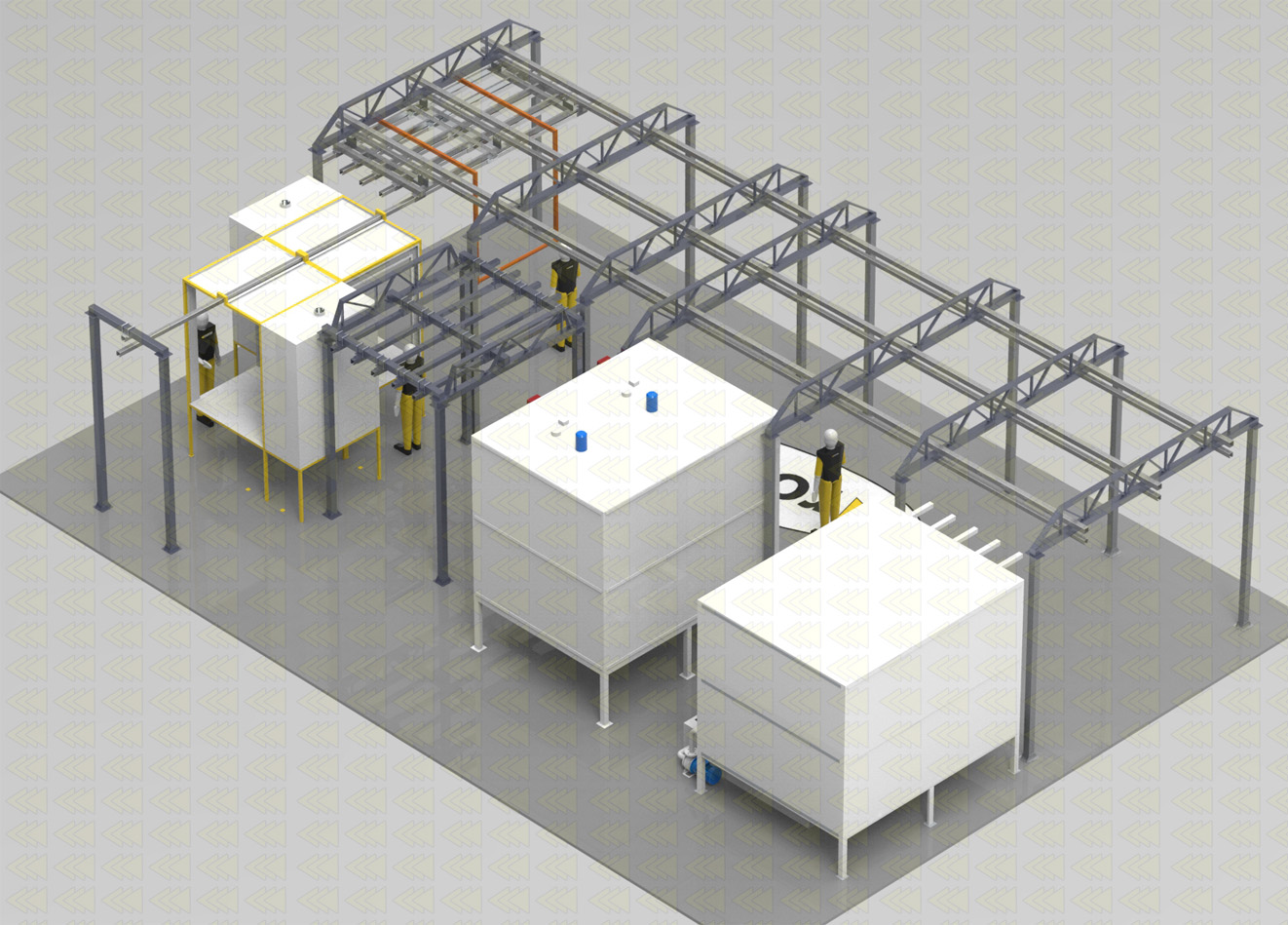

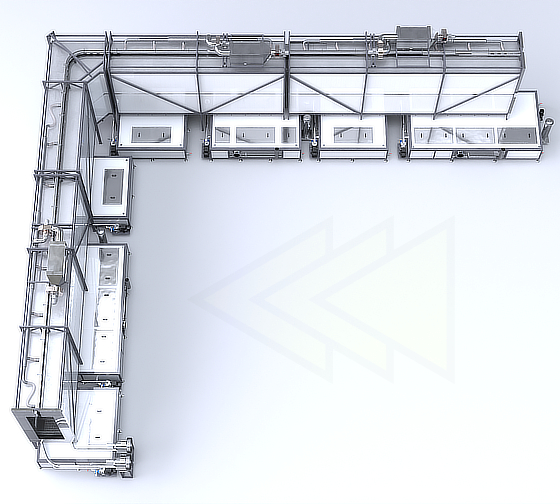

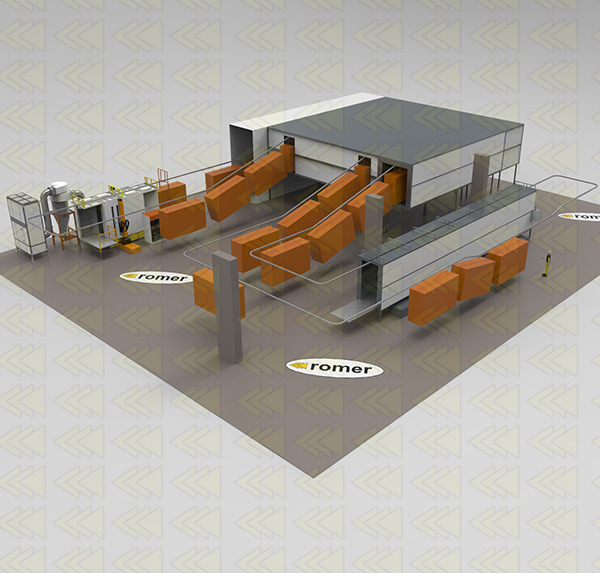

Transportsystemen

Transportsystemen

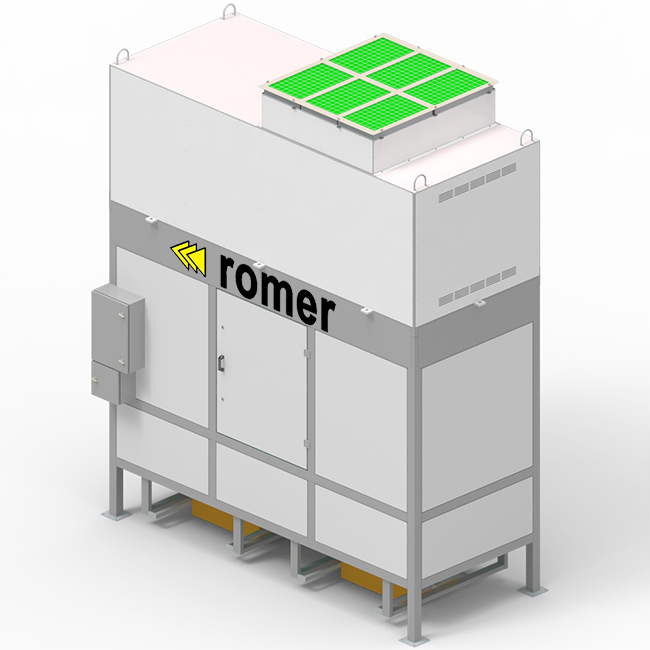

Luchtzuivering

Luchtzuivering

Verf transport

Verf transport

Systemy pomiarowe i sterowniki

Systemy pomiarowe i sterowniki

Powder coating sets

Powder coating sets

High temperature ovens

System pomiaru temperatury

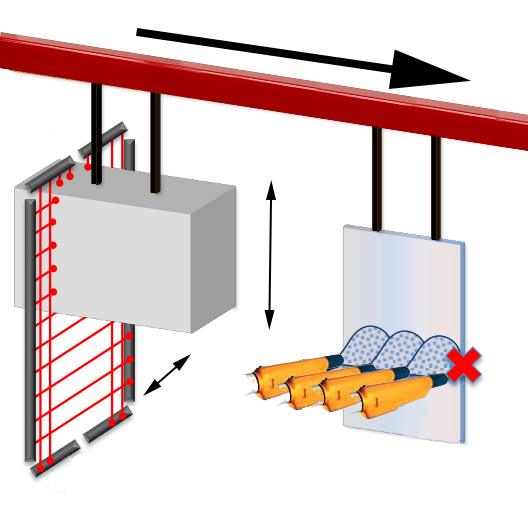

Bramka skanowania powierzchni detalu

Bramka pomiaru detalu

ProfiControl-stuurprogramma

Wykrywanie i tłumienie wybuchu

High temperature ovens

System pomiaru temperatury

Bramka skanowania powierzchni detalu

Bramka pomiaru detalu

ProfiControl-stuurprogramma

Wykrywanie i tłumienie wybuchu

Op te slaan

Citaat