Products

Paint management

Paint management

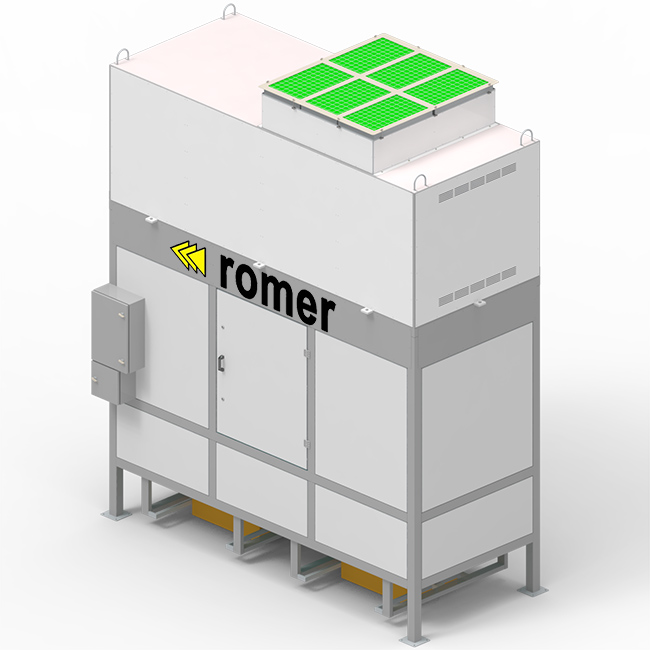

Ovens and dryers

Ovens and dryers

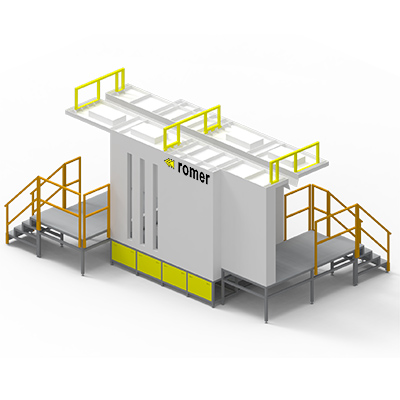

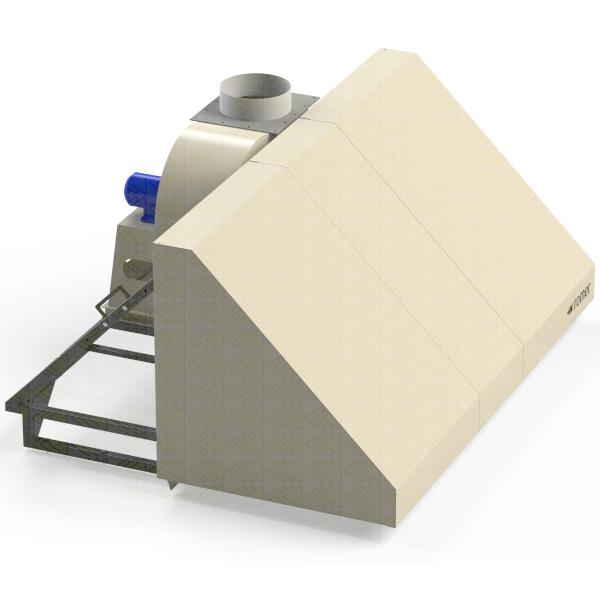

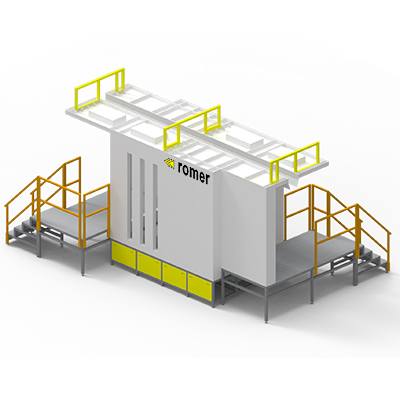

Painting booths

Painting booths

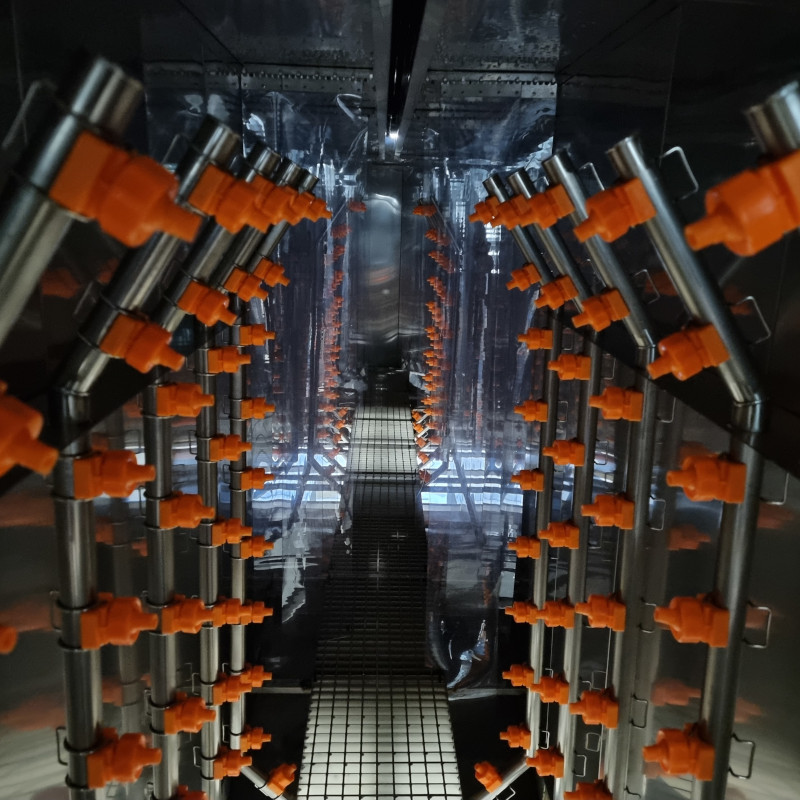

Surface preparation

Surface preparation

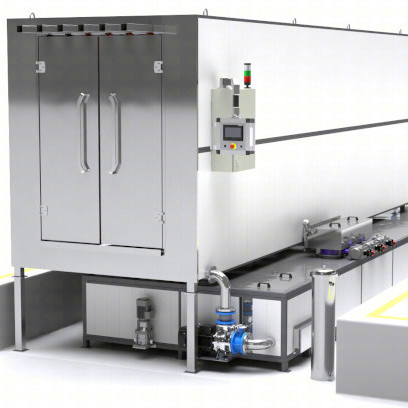

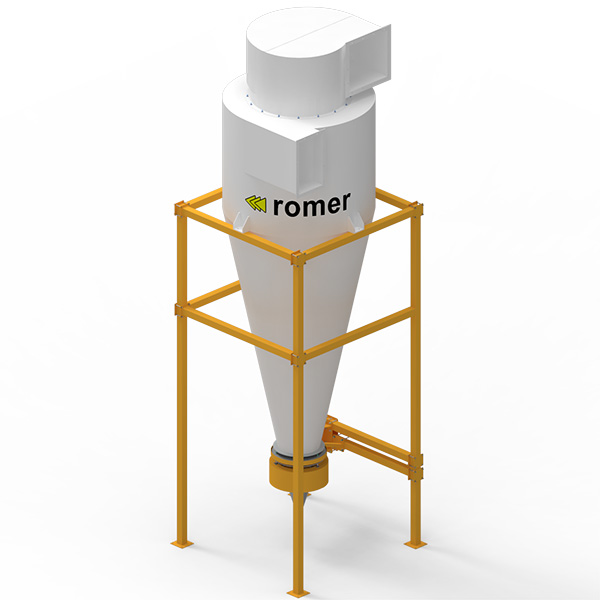

Wastewater treatment

Wastewater treatment

Powder applicators

Powder applicators

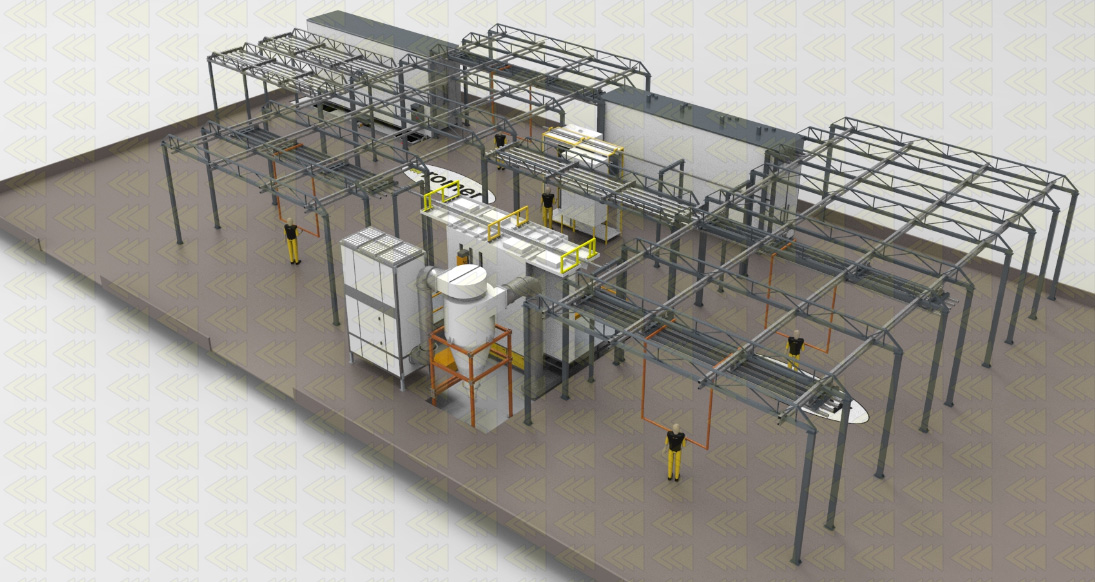

Transport systems

Transport systems

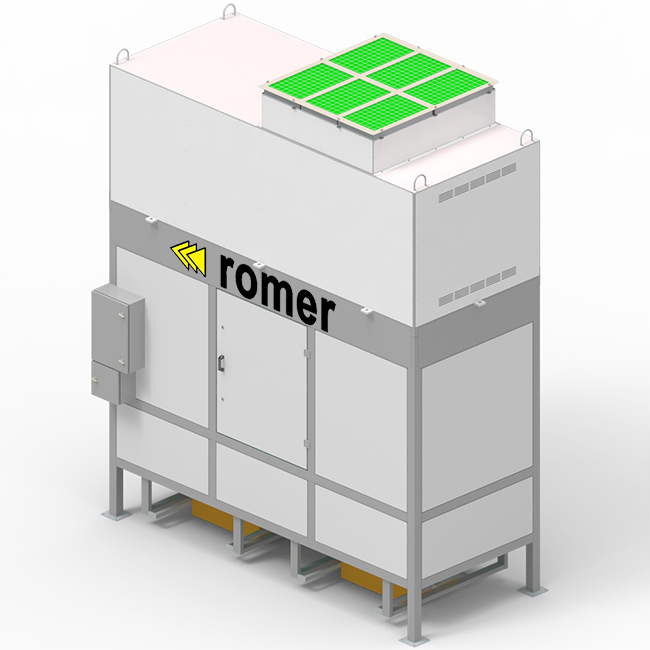

Air purification

Air purification

Transport farby

Transport farby

Measuring systems and controllers

Measuring systems and controllers

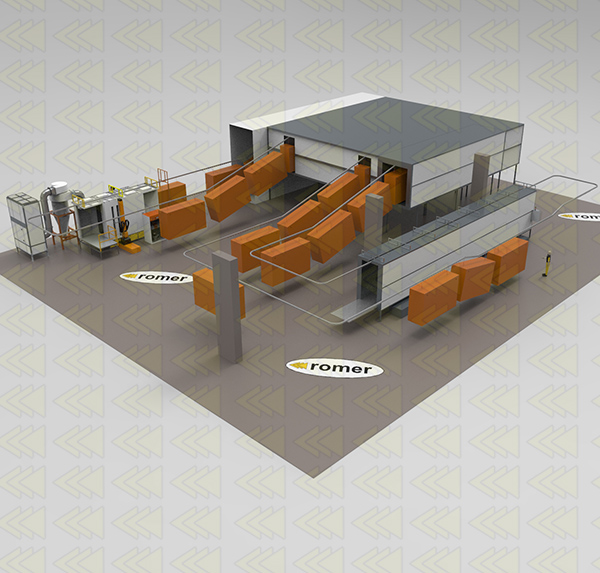

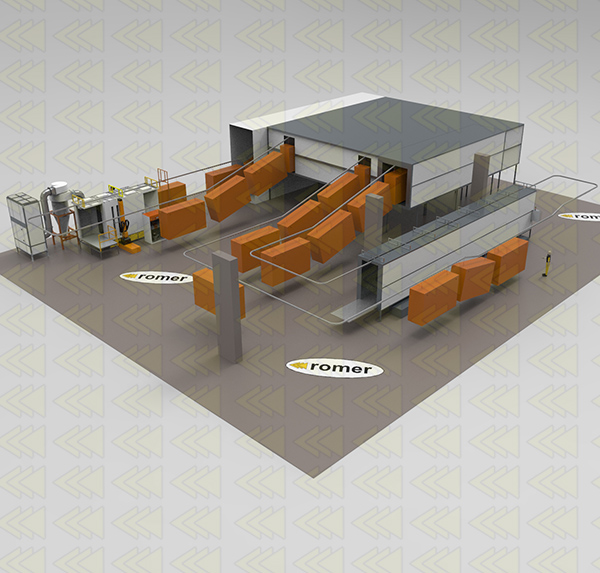

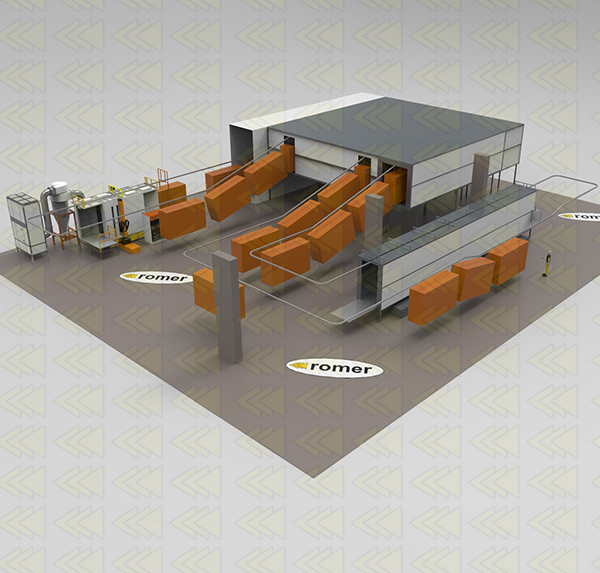

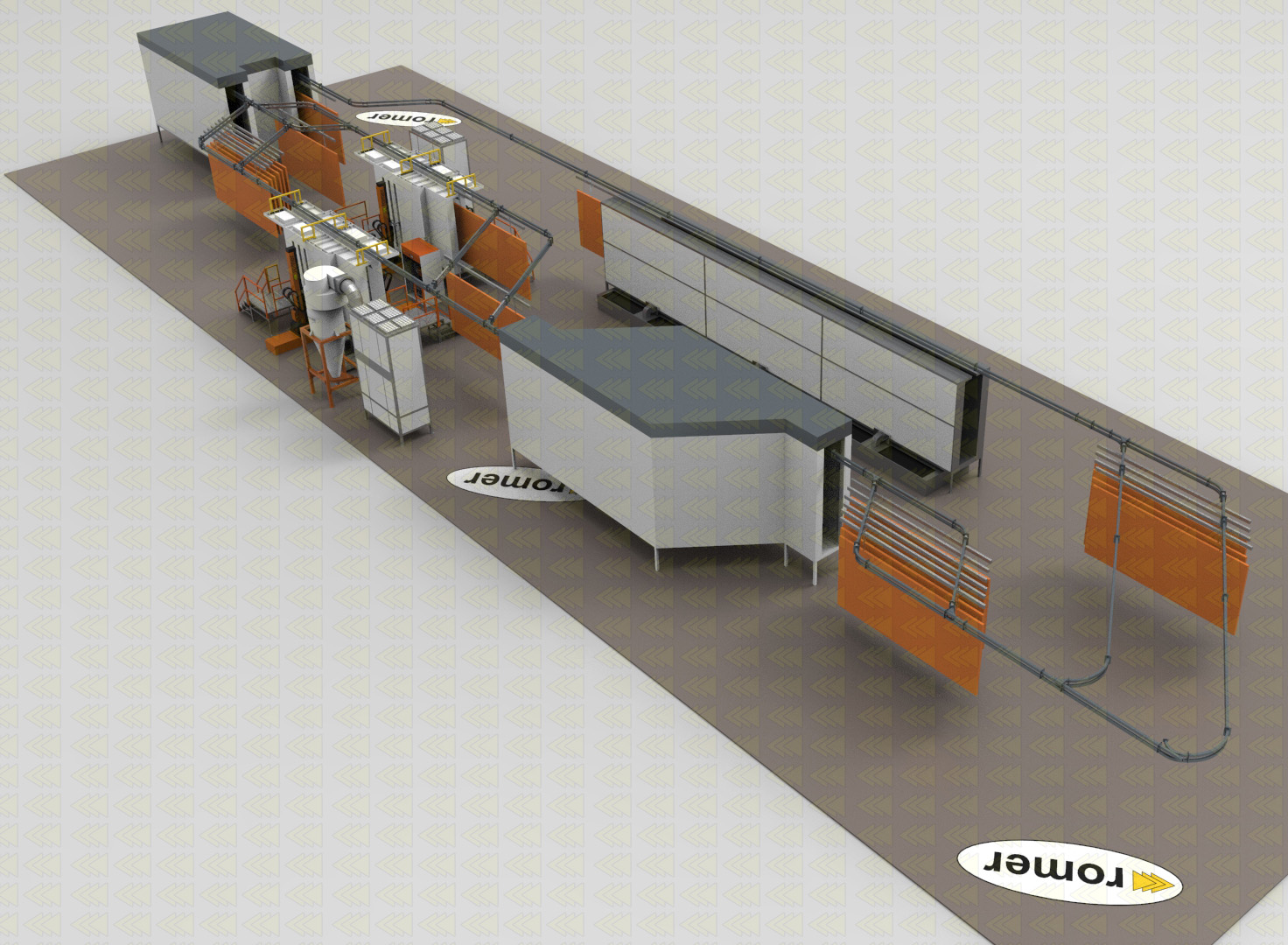

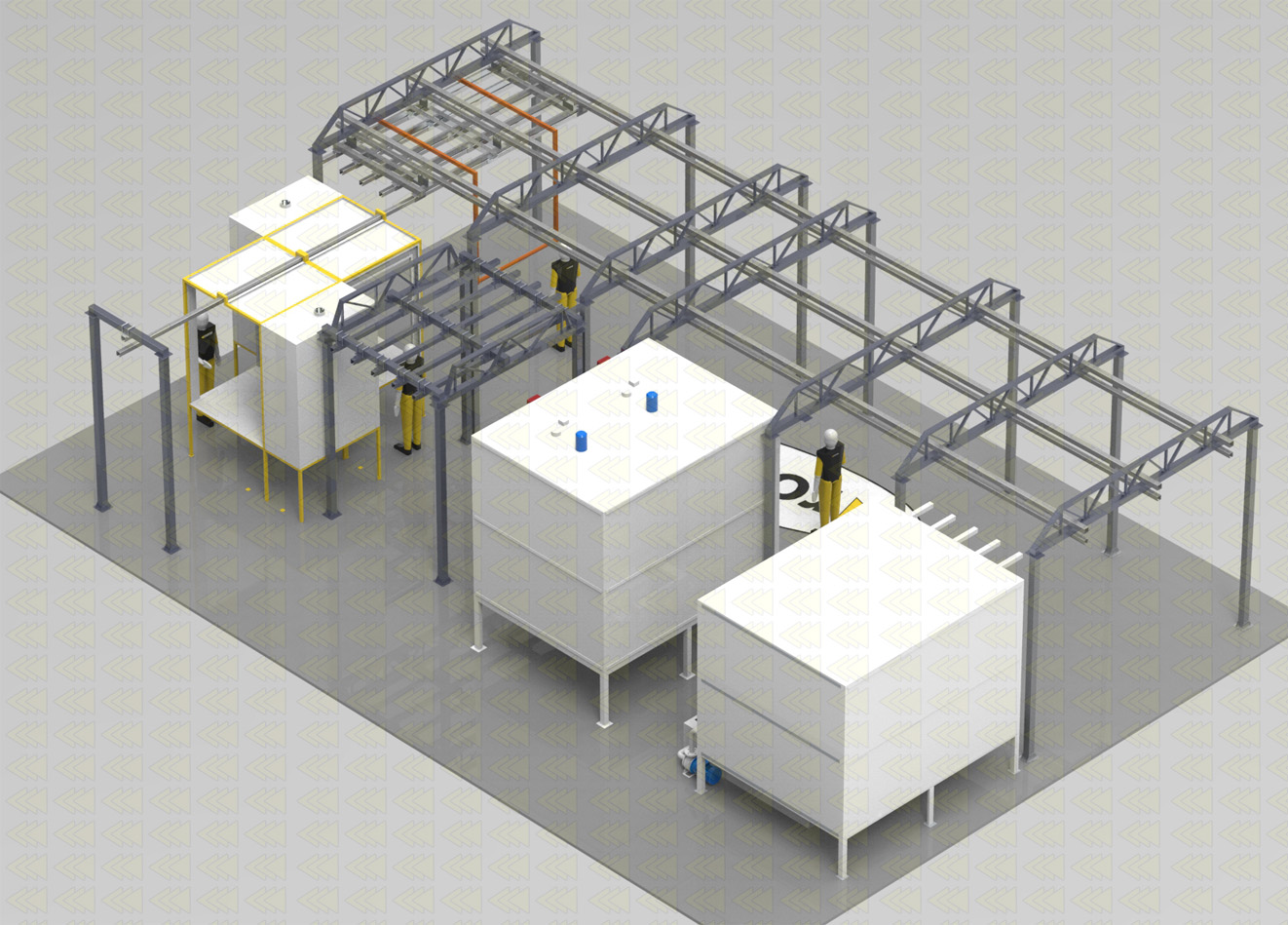

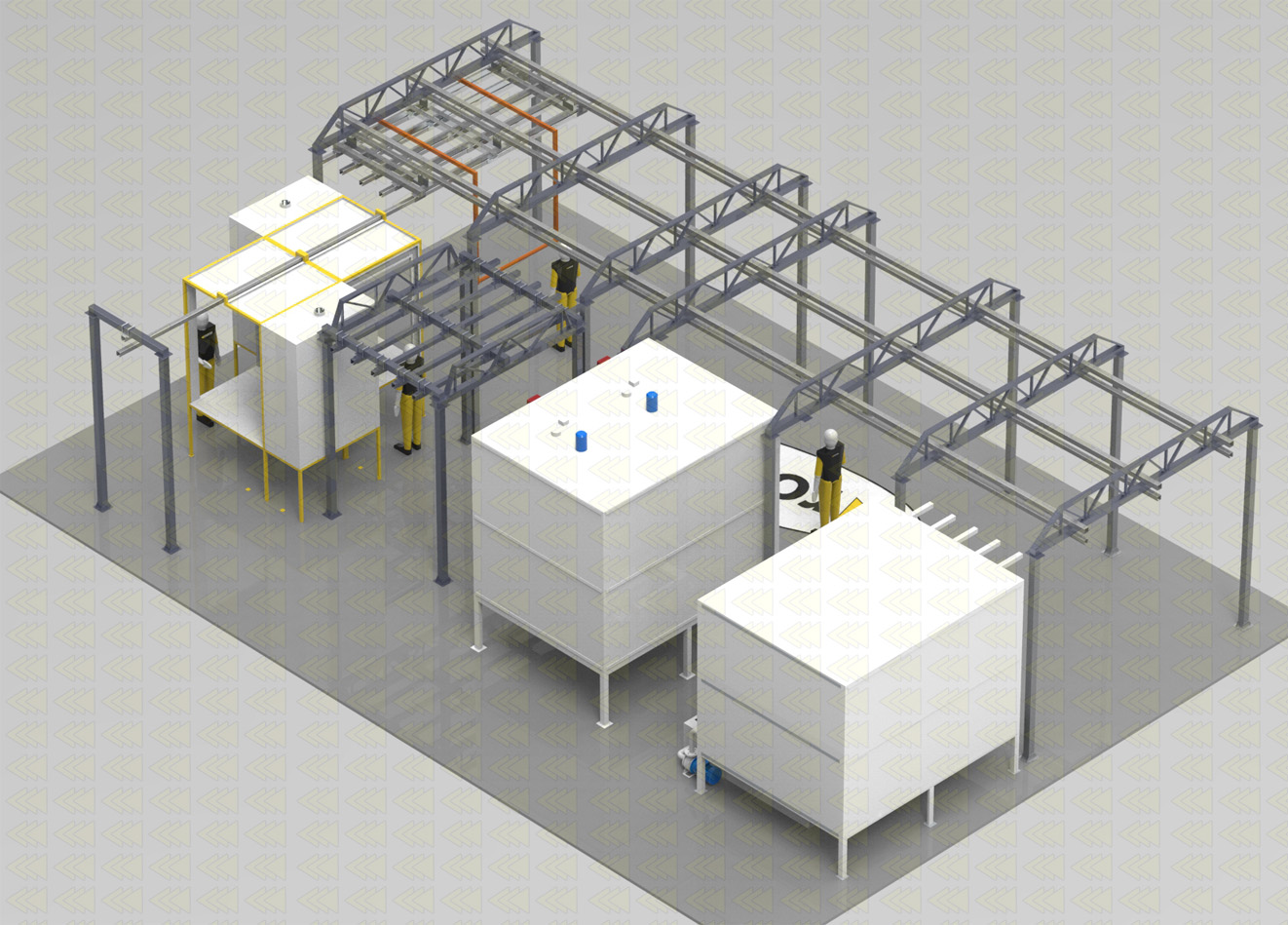

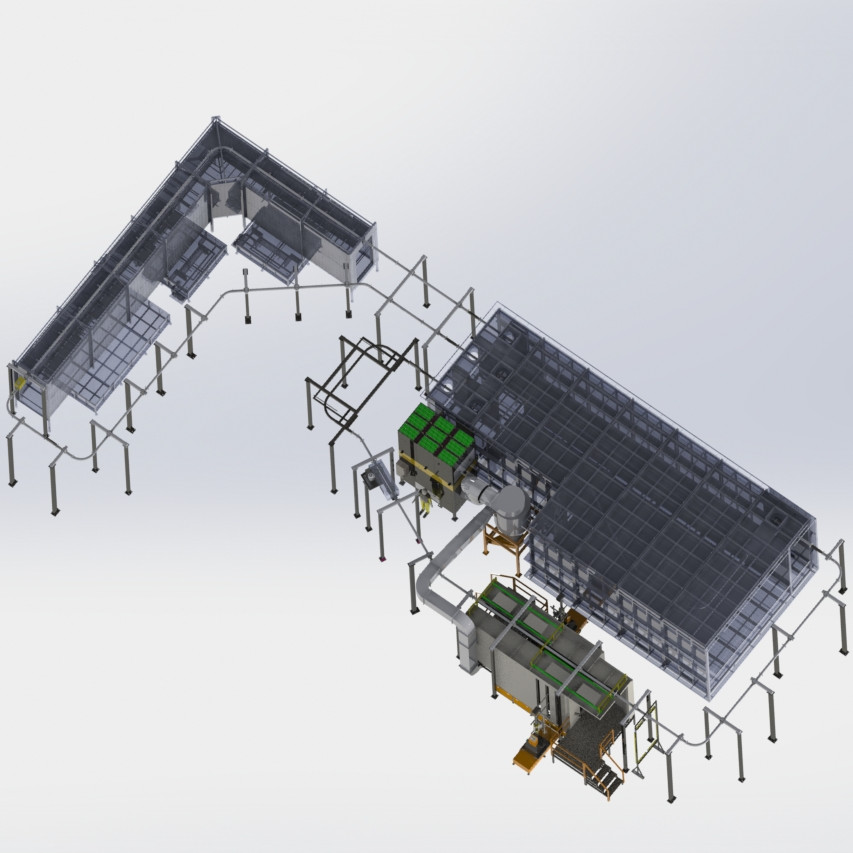

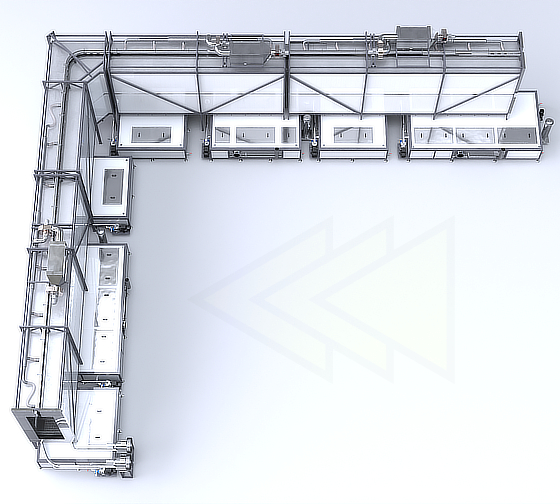

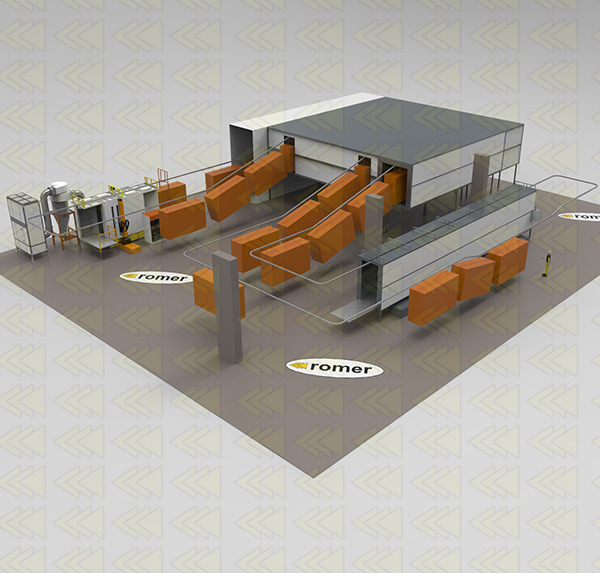

Sample configurations

Sample configurations

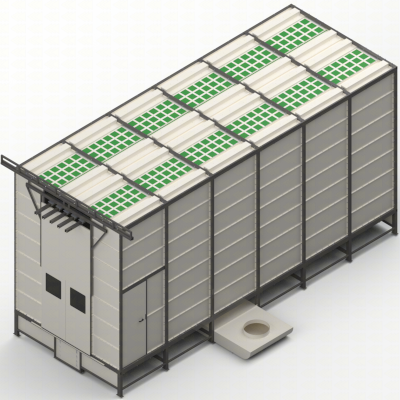

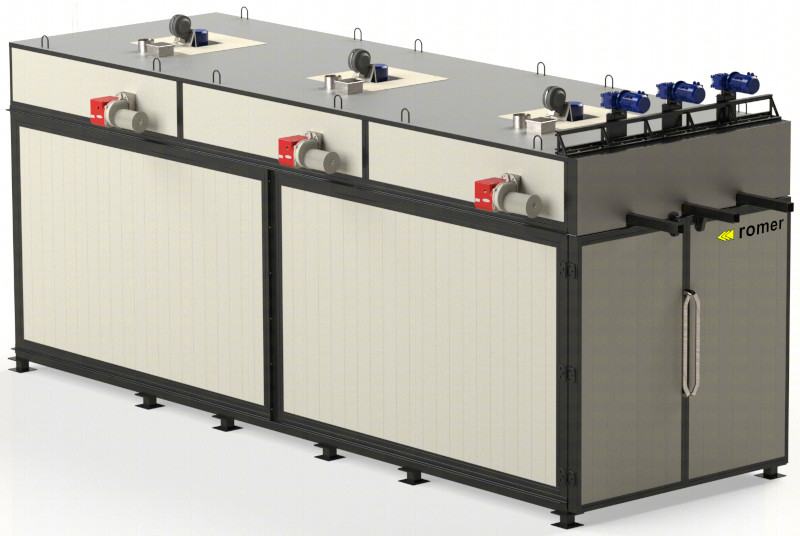

Modular tunnel furnaces

Temperature measurement system

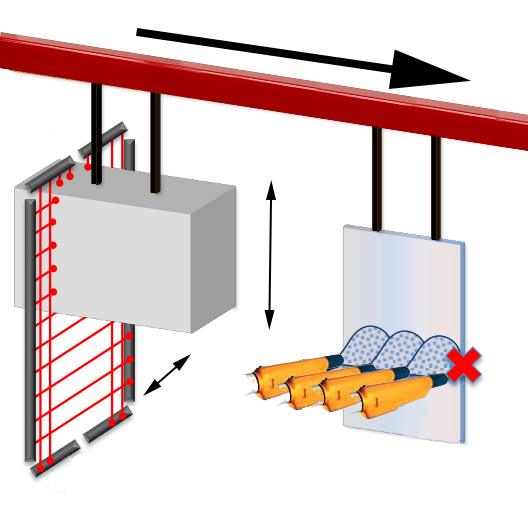

Detail surface scanning gate

Detail measurement gate

ProfiControl 10" controller

Explosion detection and suppression

Modular tunnel furnaces

Temperature measurement system

Detail surface scanning gate

Detail measurement gate

ProfiControl 10" controller

Explosion detection and suppression

Store

Quotation