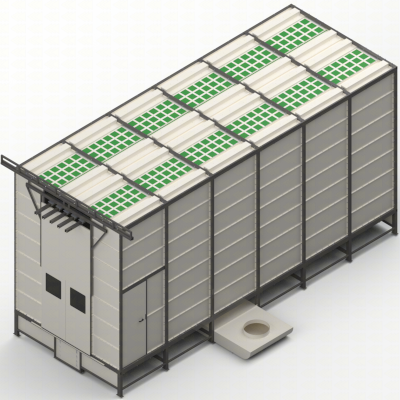

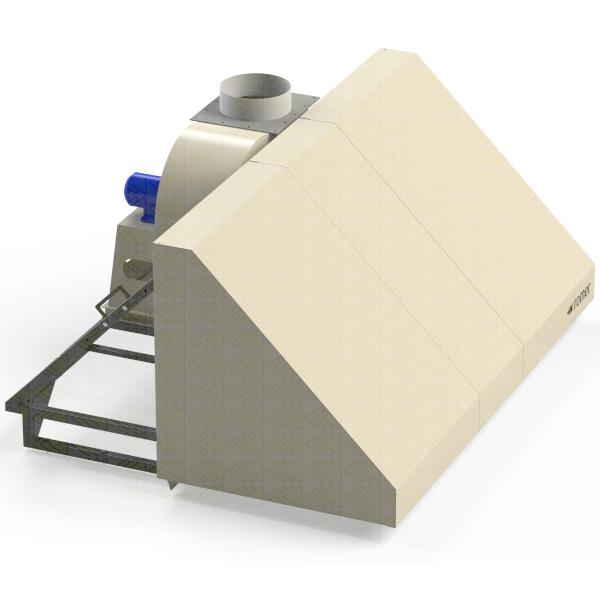

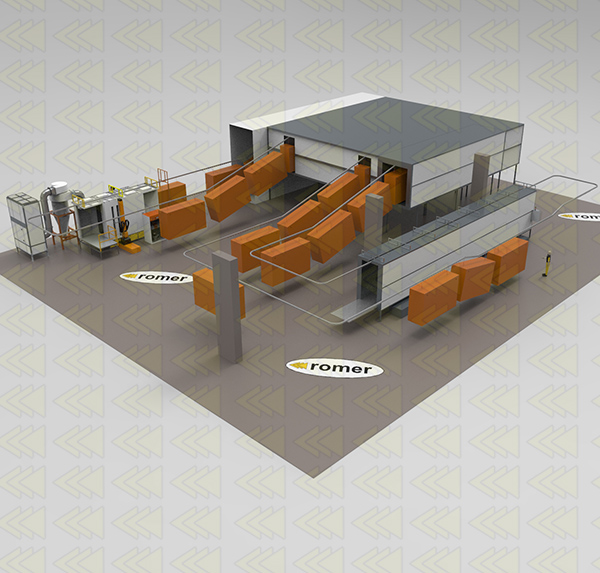

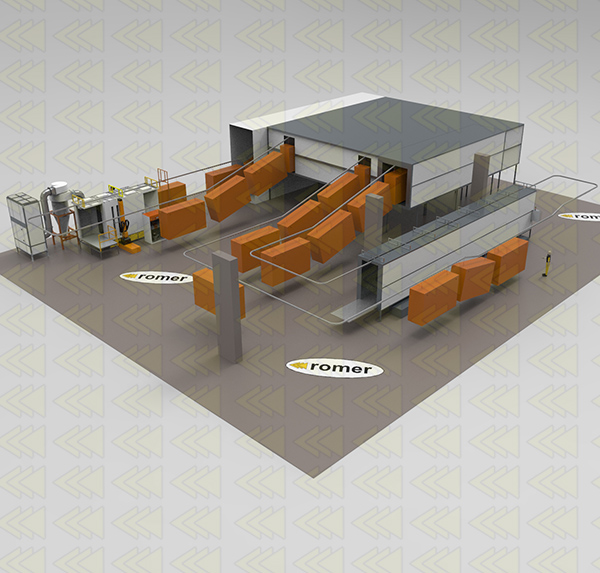

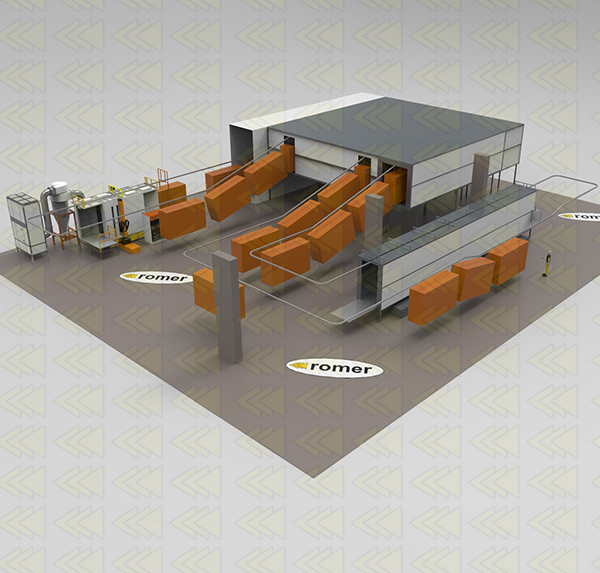

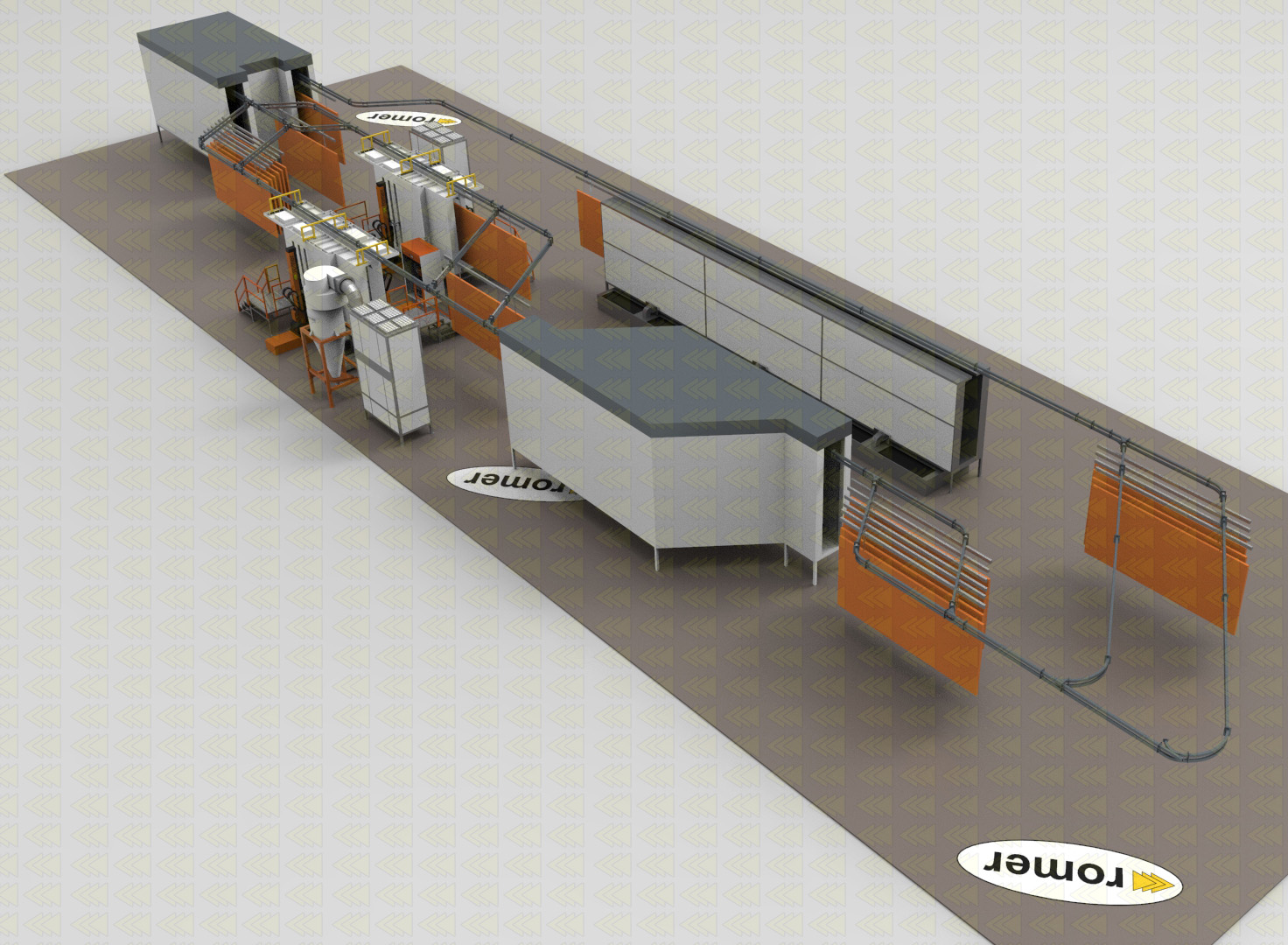

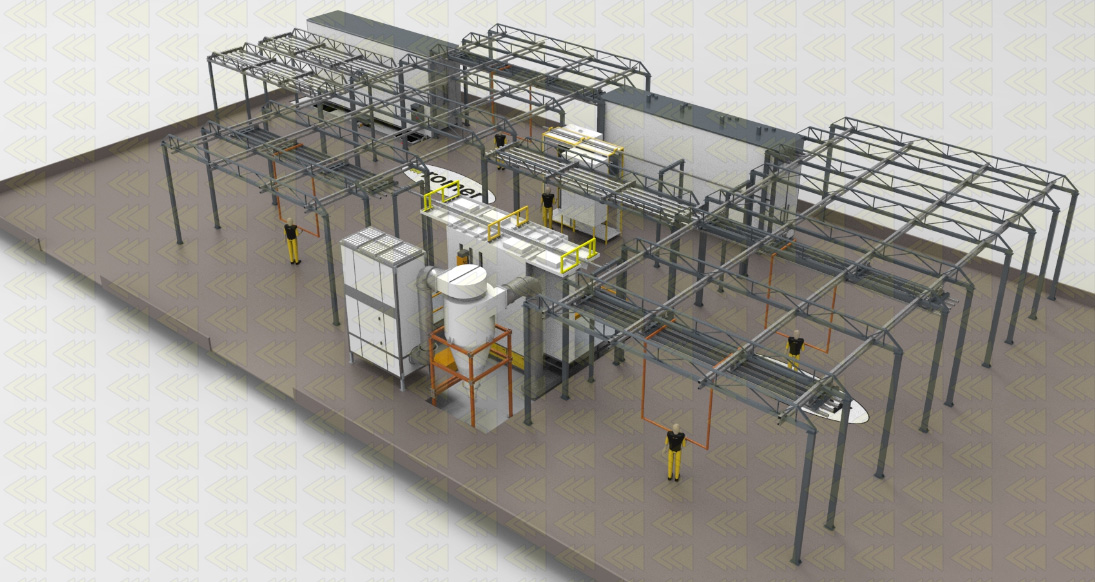

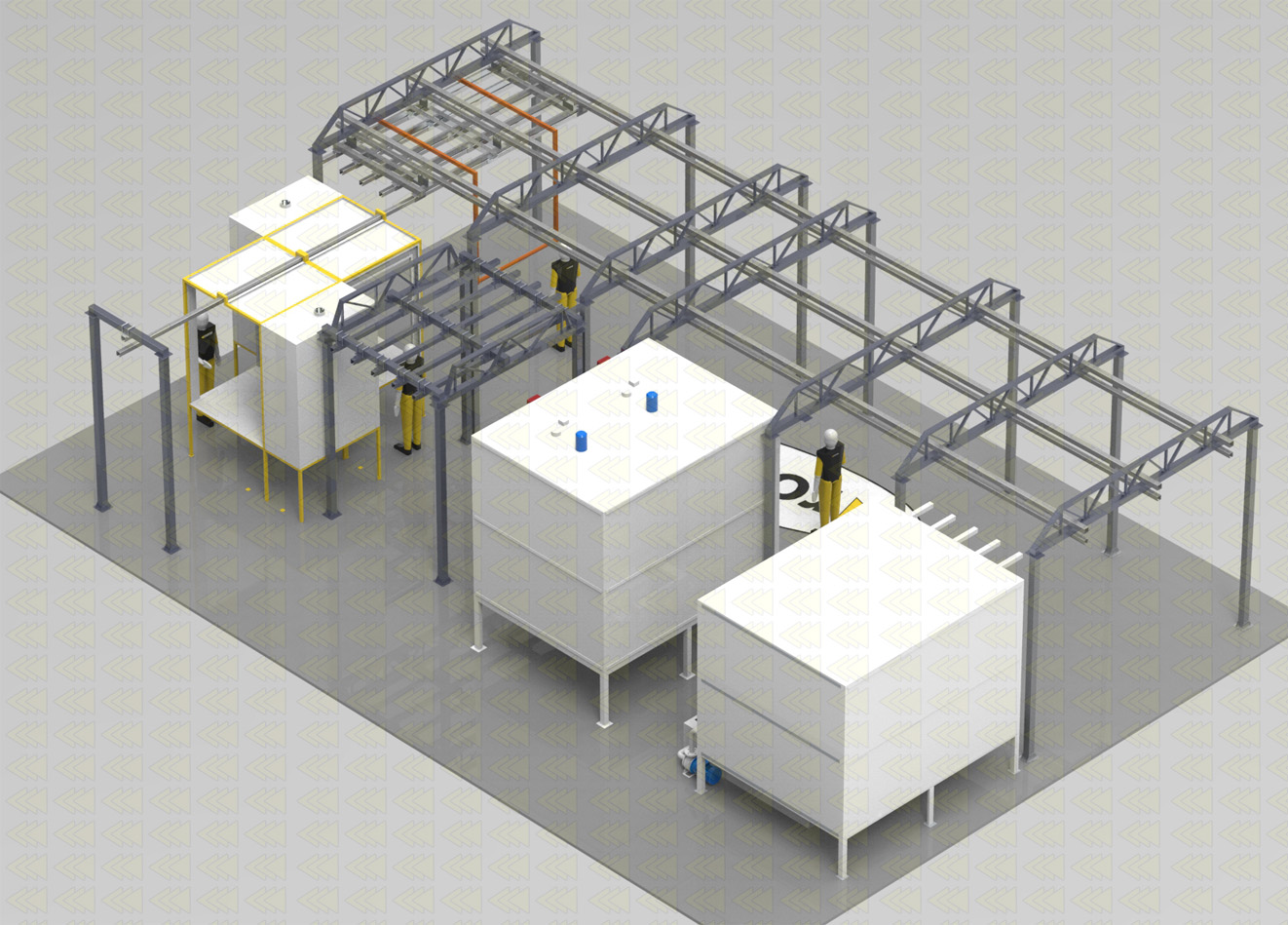

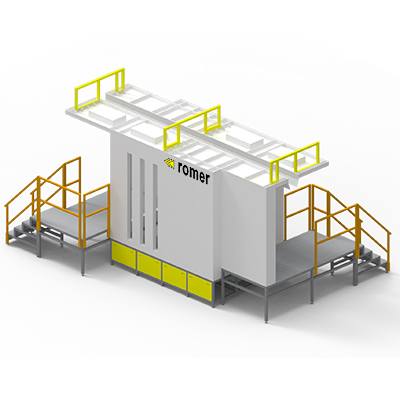

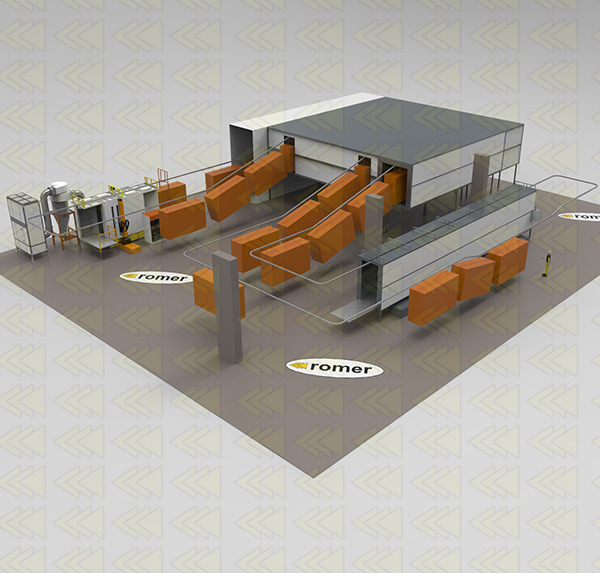

Myjki Stacjonarne do mycia ciśnieniowego dwu / trzy fazowa, fosforanowania, chromianowania, odtłuszczania .

|

Pompa ze stali kwasoodpornej |

Ciśnienie 160-200 Bar |

|

|

Nierdzewny spływ |

Obieg zamknięty |

|

|

Pamięć faz w razie odcięcia prądu

|

Automatyczne sterowanie

|

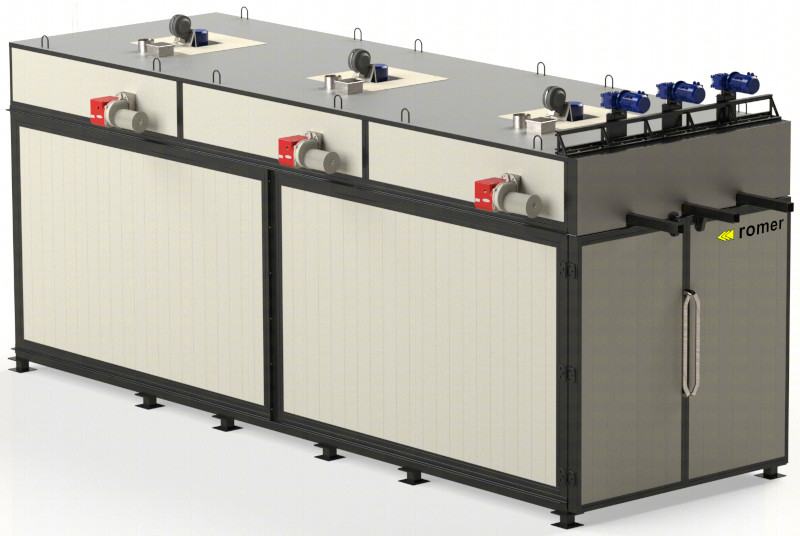

| Model | Wymiary robocze | Wymiary zewnętrzne | Moc znamionowa | Ciśń. Chemii | Ciśń. Wody |

| MS-1515 | W1500 D1500 | W2100 D1600 | 11kW | <=20 Bar | <=200 Bar |

| MS-3015 | W3000 D1500 | W3600 D1600 | 11kW | <=20 Bar | <=200 Bar |

| MS-4515 | W4500 D1500 | W5100 D1600 | 11kW | <=20 Bar | <=200 Bar |

| MS-6015 | W6000 D1500 | W6600 D1600 | 11kW | <=20 Bar | <=200 Bar |

| MS-7515 | W7500 D1500 | W8100 D1600 | 11kW | <=20 Bar | <=200 Bar |

| MS-3030 | W3000 D3000 | W3600 D3100 | 11kW | <=20 Bar | <=200 Bar |

| MS-4530 | W4500 D3000 | W5100 D3100 | 11kW | <=20 Bar | <=200 Bar |

| MS-6030 | W6000 D3000 | W6600 D3100 | 11kW | <=20 Bar | <=200 Bar |

| MS-7530 | W7500 D3000 | W8100 D3100 | 11kW | <=20 Bar | <=200 Bar |

| MS-9030 | W9000 D3000 | W9600 D3100 | 11kW | <=20 Bar | <=200 Bar |

| MS-???? | Twój wymiar | +W600 +D100 | 11kW | <=20 Bar | <=200 Bar |

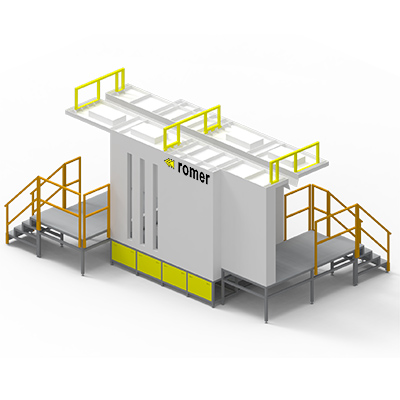

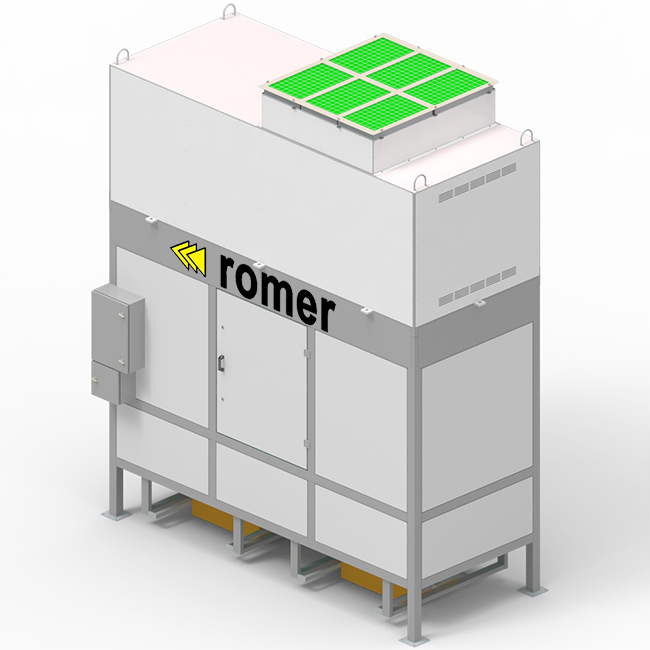

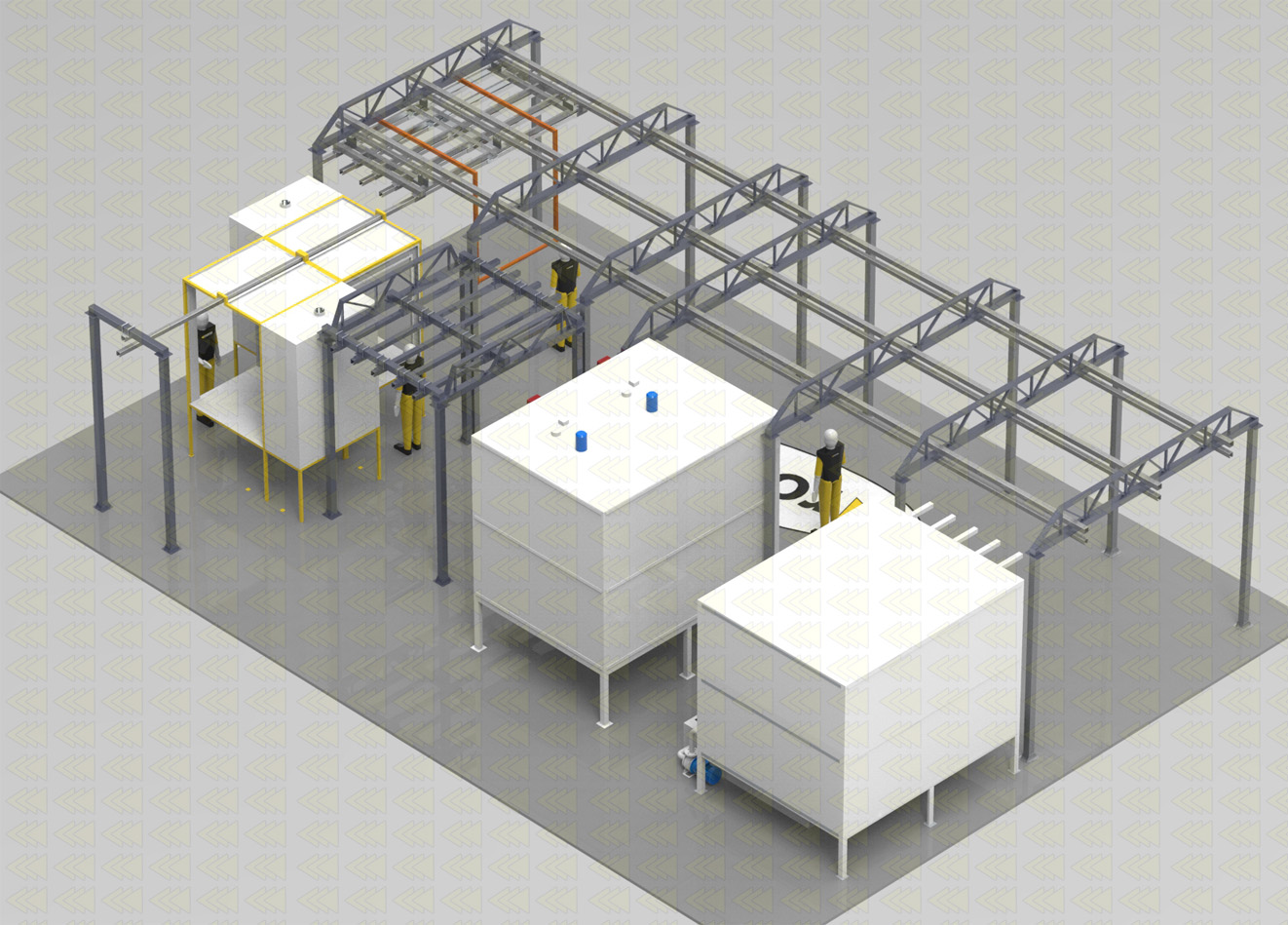

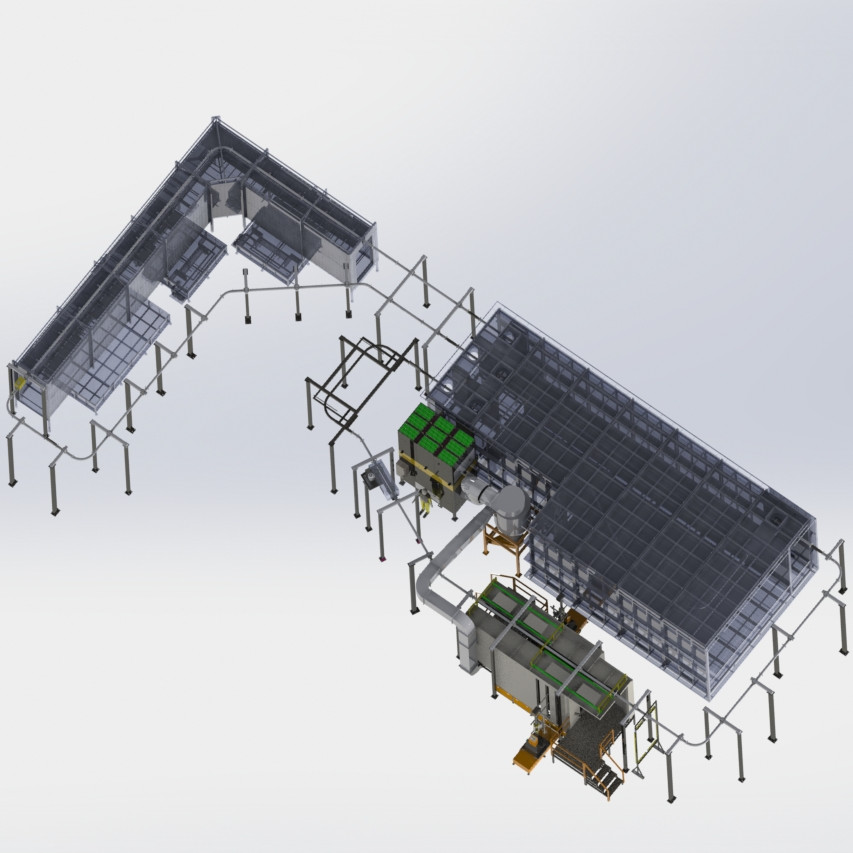

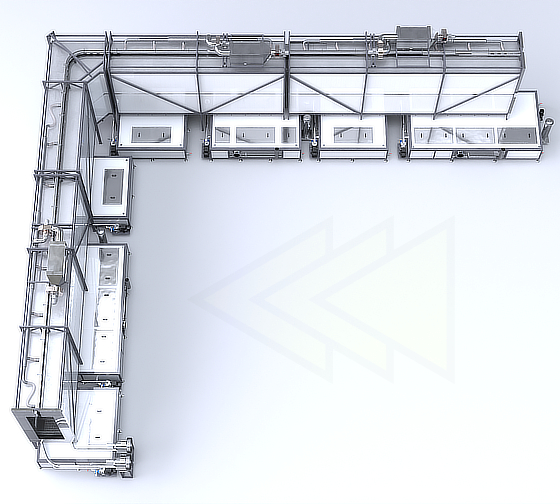

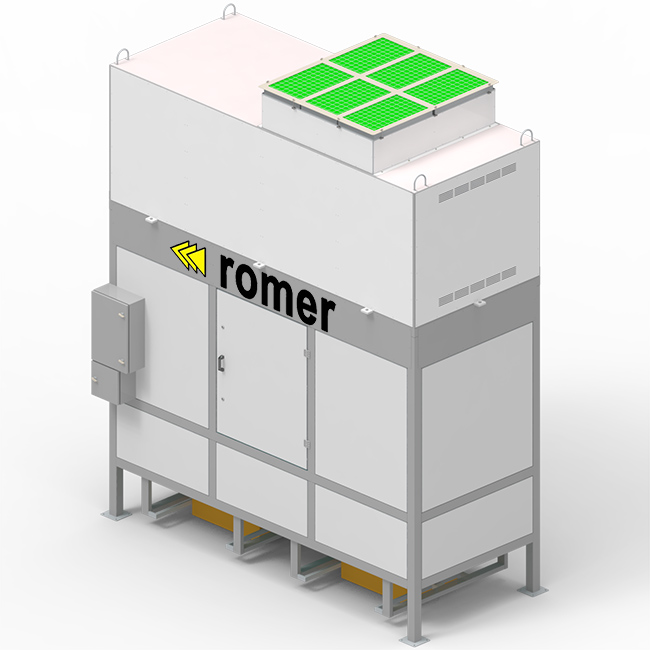

Construction

|

Modular Design |

|

Stainless worktop |

|

|

Separate return pumps |

|

Pre-filtration Each of the tops is equipped with an acid-resistant filter that catches larger elements and dirt, which will get further - fine filters are not desirable. |

|

|

Circuit filtration Since the washing liquid must be kept clean, the Phase 1 - Chemical Wash circuit has been equipped with an additional fine filter separating solid particles, which is visible to the operator. It has been equipped with a transparent body to monitor its purity on an ongoing basis. |

Advantages

|

Quick Ready |

|

Low electricity and chemical consumption |

|

|

Easy washing of dimensions |

|

Relatively low investment cost Surface preparation is the key to ensuring long-term protection against corrosion, nothing else plays such an important role in the salt spray result as surface preparation, the MC series washer is a good start, and an indispensable solution for washing large components that they do not fit into automatic tunnels or chambers. |

|

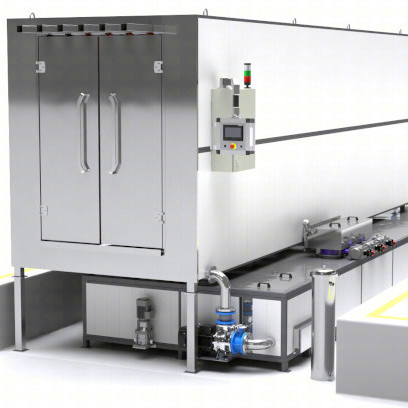

Comfort

Comfort of use thanks to which work becomes pleasant

|

4" touch panel |

|

Memory of own programs |

|

|

Information on electricity consumption |

|

Built-in car wash work calendar The calendar allows you to automatically start heating the tank at a specific time, only on working days. |

|

|

Lance stand |

|

Mixing protection In the event of a sudden power cut, the system is equipped with a special internal physical memory that works without the need for power supply. If the car wash receives the power back - it will remember when the washing was finished, preventing, for example, pumping water from tank 2 to tank 1. |

|

Industry 4.0

Solutions that allow you to create your own extensive systems

|

Programmable outputs |

|

RS485 ModBus communication |

|

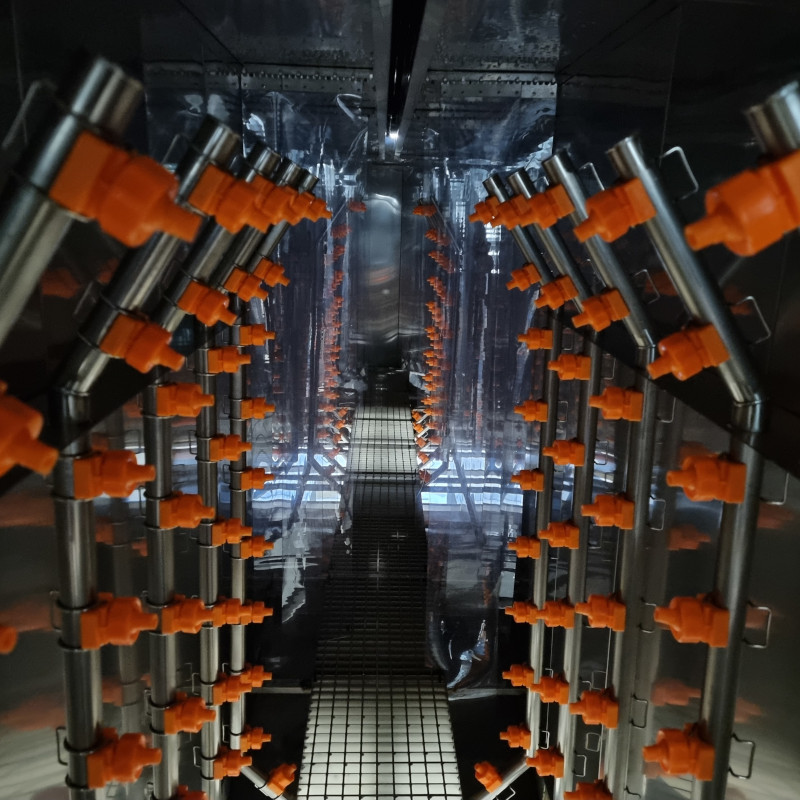

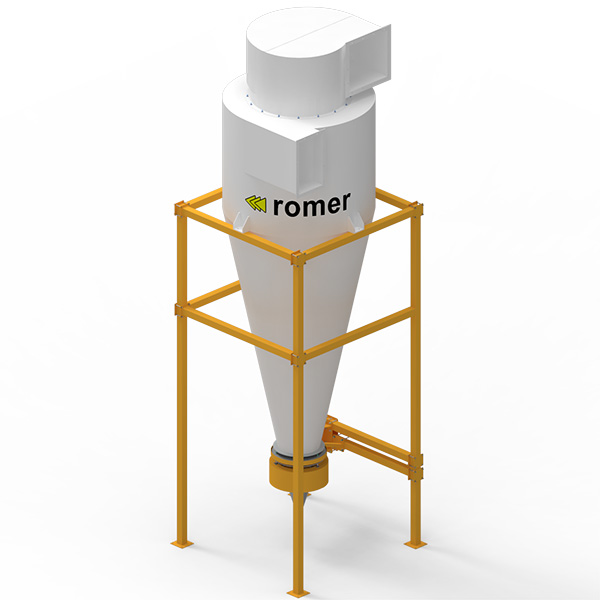

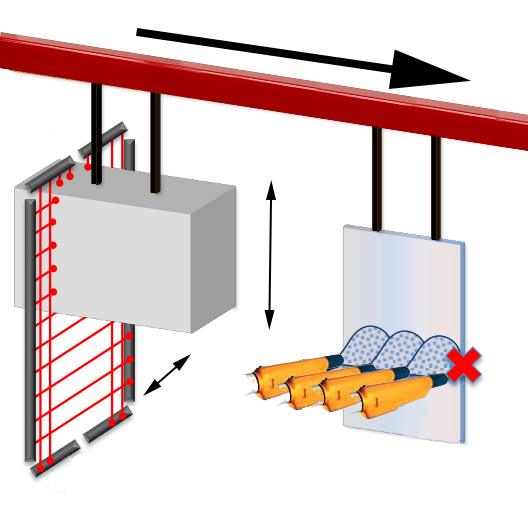

Phase 1 - Washing

|

Washing - Closed circuit |

|

High feed pressure up to 200 bar |

|

|

Rotating lance tip |

|

Gun up to 150°C with armored hose up to 300 bar It is a tool that allows you to quickly and effectively remove various types of dirt from the surface using a high-pressure water jet. These hoses are resistant to high temperatures, which allows them to be used in harsh environments, such as working near furnaces. A special perforated handle allows the high temperature of the water to be dissipated, protecting the operator's hands. |

|

|

Stainless steel high pressure pump |

Phase 2 - Rinsing

|

Rinsing - Closed circuit |

|

Stepless pressure regulation |

|

High pressure pump with ceramic pistons |

Phase 3 - DI Rinse

|

Reverse osmosis station (option) |

|

|

Rinsing with demineralized water (optional) |

|

Stepless pressure regulation |

|

High pressure pump with ceramic pistons |